SVM Bus bars

A wide range

of bus bars

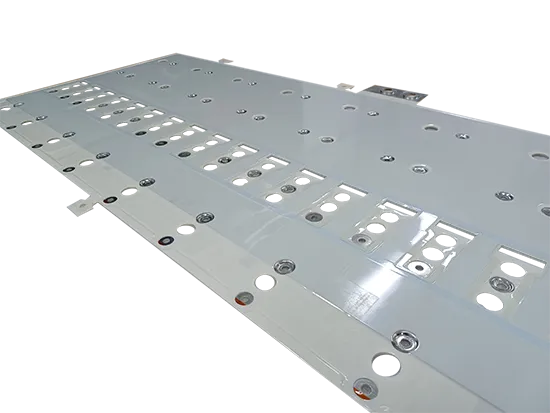

Engineered for optimal performance, Exxelia SVM copper of aluminum bus bars ensure a low inductance interconnection, critical for systems such as power converters, IGBT modules, and capacitor banks.

Exxelia SVM product offer includes:

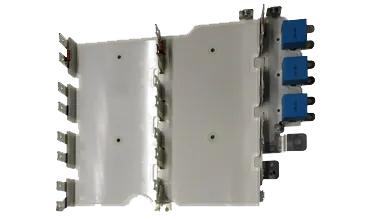

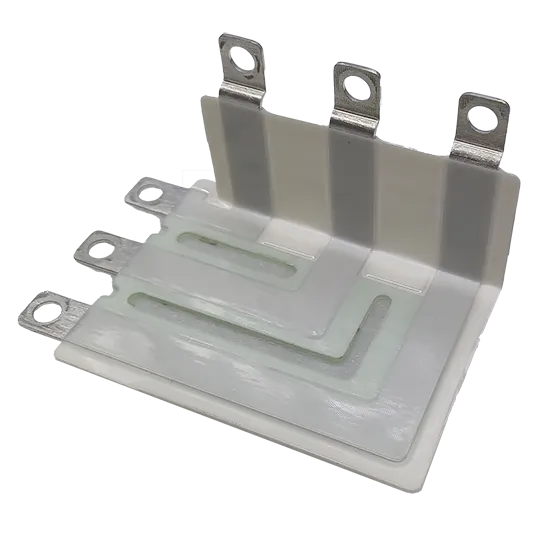

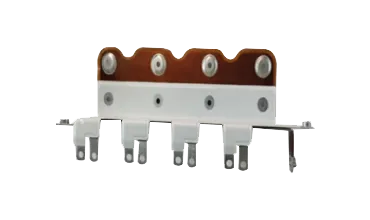

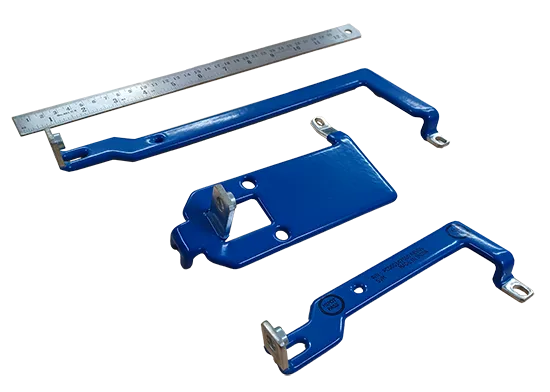

Laminated bus bars - up to 4 layers for complex requirements

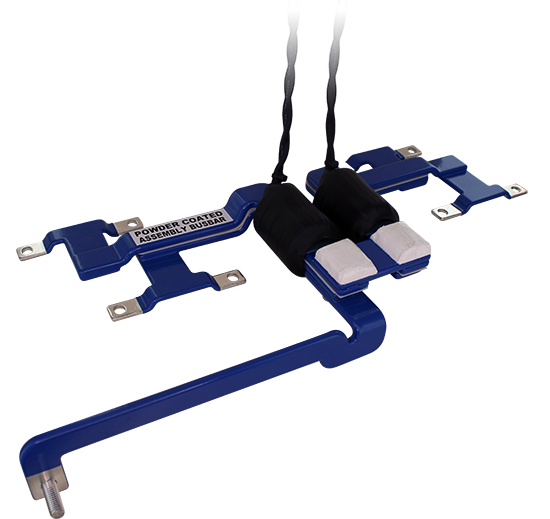

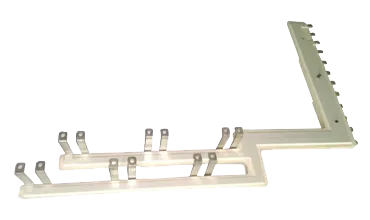

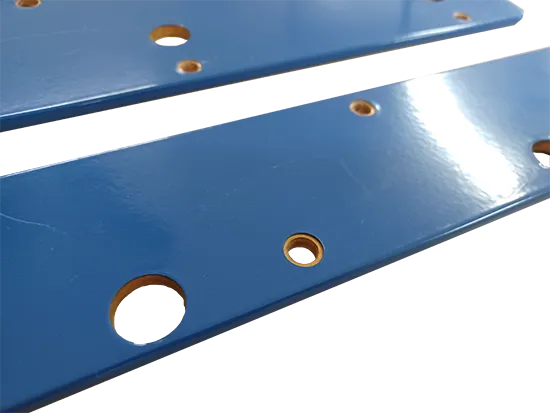

Powder coated bus bars - using epoxy powder coating for superior electrical insulation properties

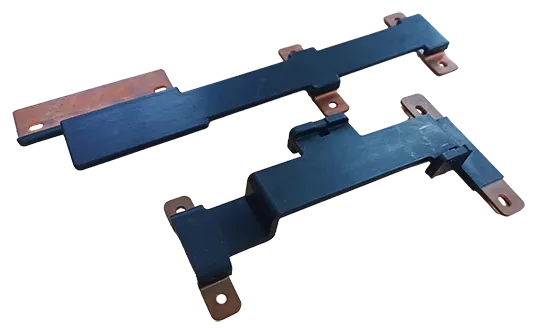

PVC molded bus bars - overmolding with Kobasol-4, a soft and flexible insulation even after molding

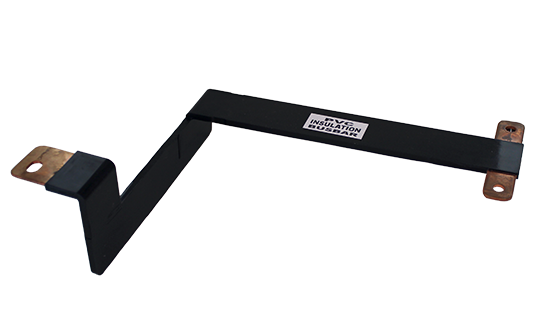

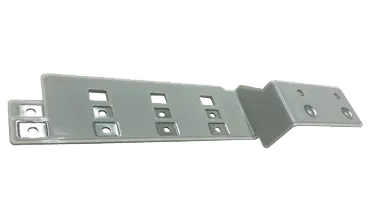

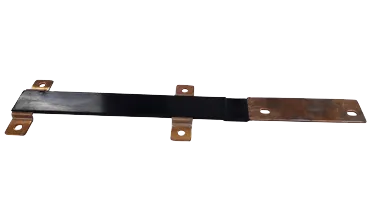

Bare copper bus bars - multiple bends / formed bus bars using Copper as per ASTM B152 C11000 (ETP)

The following finishes are also available: tin, nickel, silver or gold plating.

12+ years

of engineering

excellence in the bus bar industry

2x ISO

certifications

ISO 9001:2015 ; ISO 14001:2015; AS9100

Medical & UL norms

Expertise

IEC 60601-1, UL5085-1, UL5085-2

Plating

Tin, silver, nickel & gold

In-house plating capability

up to 4

multilayers capability

complexe design expertise

Highlighted products

Frequently Asked Questions

Laminated bus bars are interconnections using multiple layers of insulation films and copper conductors, providing compact and efficient solutions for power distribution in electronic systems.

Copper bus bars are used for the interconnection of power components such as capacitor links, DC links, IGBT power modules, and high-current inductors in applications like power electronics, solar energy, aerospace, and military.

Flexible bus bars are used for interconnecting capacitors, DC links, IGBT power modules, high-current inductors, and more in power electronics, renewable energy, aerospace, and military applications.

Resin cast bus bars are used for high-performance applications, including power distribution in industries such as renewable energy, aerospace, and electronics.

Tin plated bus bars are used for the interconnection of capacitors, DC links, IGBT power modules, and high-current inductors in power electronics, renewable energy, and aerospace applications.

The manufacturing process involves cutting insulation sheets with CNC machines, placing copper conductors between insulation films, and then laminating them.

The process involves pouring liquid epoxy resin into molds, which are then cured to form solid, high-strength busbars.

Silver plated bus bars are used for high-performance interconnections in applications such as DC links, power modules, capacitors, and high-current inductors in power electronics, aerospace, renewable energy, and military applications.

Copper bus bars offer excellent electrical conductivity, high mechanical strength, and corrosion resistance, making them ideal for power distribution and high-current applications.

Yes, we offer customized laminated busbars to meet specific requirements, including multi-layer designs and different conductor plating options.

The base material is copper (ASTM B152 C11000), and the flexible bus bars are pressure-welded with multiple layers to improve flexibility and power density.

They are made using bisphenol-A epoxy resin, providing durable insulation and reliable performance.

Tin plating provides excellent corrosion resistance and enhances solderability, making these busbars suitable for a wide range of environmental conditions.

They offer easy bending, improved assembly flexibility, smaller size compared to cables, and better power density, reducing installation time and costs.

They are used in power electronics, renewable energy (solar, wind), aerospace, military, and transportation sectors, often in applications like DC links, IGBT power modules, and high-current inductors.

These bus bars are used for high-performance interconnections in applications such as DC links, power modules, capacitors, inductors, and other high-current components in industries like power electronics, aerospace, and renewable energy.

The base material is copper (ASTM B152 C11000) with silver plating according to ASTM B700 standards.

They offer compact designs, reduced weight, enhanced performance, and easier integration into electronic systems.

Silver plating provides excellent solderability, low contact resistance, and good adhesion over copper and nickel, making it suitable for high-performance electrical connections.

The base material is copper (ASTM B152 C11000), which is Electrolytic Tough Pitch (ETP) copper.

Kobosol insulated bus bars offer excellent dielectric strength of 11 kV/mm and are available in insulation thicknesses ranging from 0.5mm to 4mm.

The base material is copper (ASTM B152 C11000), with tin plating according to ASTM B545 and ISO 2093 standards.

These bus bars are ideal for power electronics, renewable energy, aerospace, military applications, and transportation.

Yes, these bus bars are designed to handle high currents, making them ideal for power and measuring components.

These bus bars are ideal for power electronics, renewable energy, aerospace, military applications, and transportation.

They are made using ETP copper (99.9% pure), insulation materials like FR4 or G10, and flame glass (UL 94 V-0) for insulation.

The base material is copper (ASTM B152 C11000), with nickel plating according to ASTM B733 and gold plating according to ASTM B488.

Kobosol is a flexible PVC insulation material used to insulate busbars, providing electrical insulation and ensuring dielectric strength.

Industries such as power electronics, wind energy, solar energy, aerospace, military, and transportation benefit from using AkzoNobel Epoxy Insulation Coating for their busbars.

This coating offers excellent chemical, heat, and moisture resistance, along with strong adhesion to conductors like copper and aluminum, making it suitable for demanding environments.

AkzoNobel Epoxy Insulation Coating is used to provide electrical insulation and protection for busbars in various high-performance applications, including power electronics, renewable energy, and aerospace.

Powder coated busbars are electrical conductors, typically made of copper or aluminum, that have been coated with an epoxy powder to provide electrical insulation and protection against environmental factors. This coating enhances durability and ensures safety in various applications.

SVM's powder coated bus bars utilize conductors made from high-conductivity materials such as copper and aluminum, ensuring efficient electrical performance.

The epoxy powder coating offers several advantages:

- Electrical Insulation: Provides a high dielectric barrier, reducing the risk of short circuits.

- Durability: Enhances resistance to chemicals, heat, moisture, and mechanical wear.

- Corrosion Resistance: Protects the underlying metal from environmental degradation.

- Safety: Reduces the risk of electrical shock to personnel.

Yes, SVM's powder coated bus bars comply with flame class UL-94 V-0 and are RoHS compliant, ensuring they meet stringent safety and environmental standards.

Powder coating offers a uniform and durable insulation layer that conforms to complex geometries, providing better protection against environmental factors compared to traditional insulation methods like tapes or sleeves. It also allows for closer spacing between bus bars, improving system compactness.

Exxelia is certified EN 9100, a quality standard specific to the aerospace, space, and defense sectors. Our facilities are also ISO 9001 certified (quality management), and some are certified ISO 13485 for medical devices. Other industry-specific standards, such as NADCAP or AQAP, may also apply depending on the products and markets.

The EN 9100 standard ensures a rigorous quality management system tailored to the critical requirements of the aerospace, space, and defense industries. It is required by major OEMs such as Airbus, Safran, Thales, or CNES. This certification guarantees product traceability, risk management, and compliance with international standards.

Yes, some of our facilities are ISO 13485 certified, the quality standard for medical devices. This certification enables Exxelia to design and manufacture components (such as coils, sensors, or capacitors) used in high-reliability medical equipment, including MRI scanners, ventilators, and imaging systems.

The railway industry demands durability, reliability, and long service life. While a dedicated certification like EN 9100 is not required, Exxelia applies IRIS standards and complies with IEC/EN regulations specific to railway applications. Our quality processes ensure component compliance for trains, metros, and tramways, including fire safety and electromagnetic compatibility.

Yes. Exxelia meets defense industry requirements through its EN 9100 certification and compliance with military standards (MIL-STD, STANAG). Our components are qualified for critical applications such as RF systems, embedded electronics, guided munitions, or radar systems. Some products are also subject to customer-specific qualification procedures.

Exxelia SVM is a company within the Exxelia Group with over 35 years of experience in the design, development, and manufacturing of coils and transformers, for both high-frequency and low-frequency applications. This extensive expertise allows Exxelia SVM to offer reliable technical solutions tailored to a wide range of demanding and often critical requirements.

For more than 12 years, Exxelia SVM has also specialized in the design and production of busbars with a variety of technologies and finishes, including:

epoxy powder coating,

PVC coating,

laminated busbars,

flexible busbars,

resin-cast busbars,

and surface finishes such as nickel plating, gold plating, silver plating, brazing, and tin plating.

These busbars are used in demanding environments, particularly in the healthcare and automotive industries, where high quality, reliability, and performance are essential.

Exxelia SVM’s mission is to address the complex and critical needs of design and manufacturing engineers in the electronics and electrical industries. The company supports its customers from design to mass production, offering full technical support to turn design concepts into manufacturable products.

With its long-standing experience in the design of transformers, inductors, and various electromagnetic components, Exxelia SVM continuously improves product quality. This know-how also enables productivity gains without compromising quality, ensuring consistent performance and competitive pricing for its customers.

Exxelia SVM is also characterized by strong vertical integration, which provides a high degree of flexibility and self-sufficiency in its manufacturing processes. This integration includes:

the design of bobbins,

the design and fabrication of injection molds,

the manufacture of bobbins using both thermoset (phenolic) and thermoplastic materials, from standard to high-performance grades,

an in-house tool room for precision machining of plastics and metals to meet exacting specifications, especially for rigid mounting systems,

the design and production of customized packaging materials to meet specific transportation needs, whether by road, air, or sea.

With a monthly production capacity exceeding 10 million parts, Exxelia SVM is one of the largest manufacturers of coils and transformers in India, serving low-, mid-, and high-volume production demands.

Exxelia SVM’s components are used across a variety of sectors, including:

power supply,

lighting,

medical electronics,

electric vehicles,

automotive,

communications,

and many other industrial electronic applications.

Exxelia SVM serves international customers in the United States, Israel, France, China, and India, demonstrating its ability to meet global technical, regulatory, and logistical standards across a wide range of industries.

Exxelia SVM PRIVATE LIMITED is committed to satisfy its interested parties by providing quality products and on time delivery meeting customers’ and statutory and regulatory requirements. This could be achieved by involving all in the organization and continually improve the effectiveness of Quality Management Systems.

And Exxelia SVM is committed to protect, conserve and enhance aspects of the environment over which we have control or can influence.

These will be achieved through commitment on

- Strive to minimize waste and conservation through pollution prevention.

Continually improve the effectiveness of Environmental Management System - Meeting the compliance with Applicable Legal and Other Requirements.

- Conservation of resources like Oil, Water, Electrical energy, Packing material etc

- Instilling awareness to the employees for maintaining a pollution free environment

- Maintain open communication with public and other interested parties regarding Environment, Health and Safety.

Exxelia SVM is an ISO 9001:2015, ISO 14001:2015 Certified Organization and we comply with all Statutory Laws and Regulations.

Our Quality and Production Engineers are certified as per IPC-WHMA-A-620C (Requirements and Acceptance for Cable and Wire Harness Assemblies), IPC J-STD-001 (Requirements for Soldered Electronic Assemblies) & IPC-A-610 (Acceptability of Electronic Assemblies), IPC-A-600 (Acceptability of Printed Boards)

Exxelia SVM products are recognized under UL Insulation Systems

UL File No: E251904

- Class 130 (B) coil and transformer insulation systems designated CIS.04, SIS-130

- Class 155 (F) electrical insulation systems designated SIS-155- 1

Compliance to Safety and Regulatory Standards

- IEC 60601-1, UL 60601, ES 60601-1:2005

- IEC 61558-2- 13, IEC 61558-2- 4

- UL 5085-1, UL5085-2

Reliability Standards

IEC62211 Level B (Vibration test, Drop test, Humidity test, Solder-ability test, Temperature cycle test, Continuous Vibration test)

ROHS, REACH and Packaging Regulations.

Exxelia SVM is the registered member in BOMcheck for Regulatory Compliance Declarations.

The Team at Exxelia SVM works closely with our Customers and Suppliers to establish the highest Quality Standards.

Still have questions ?