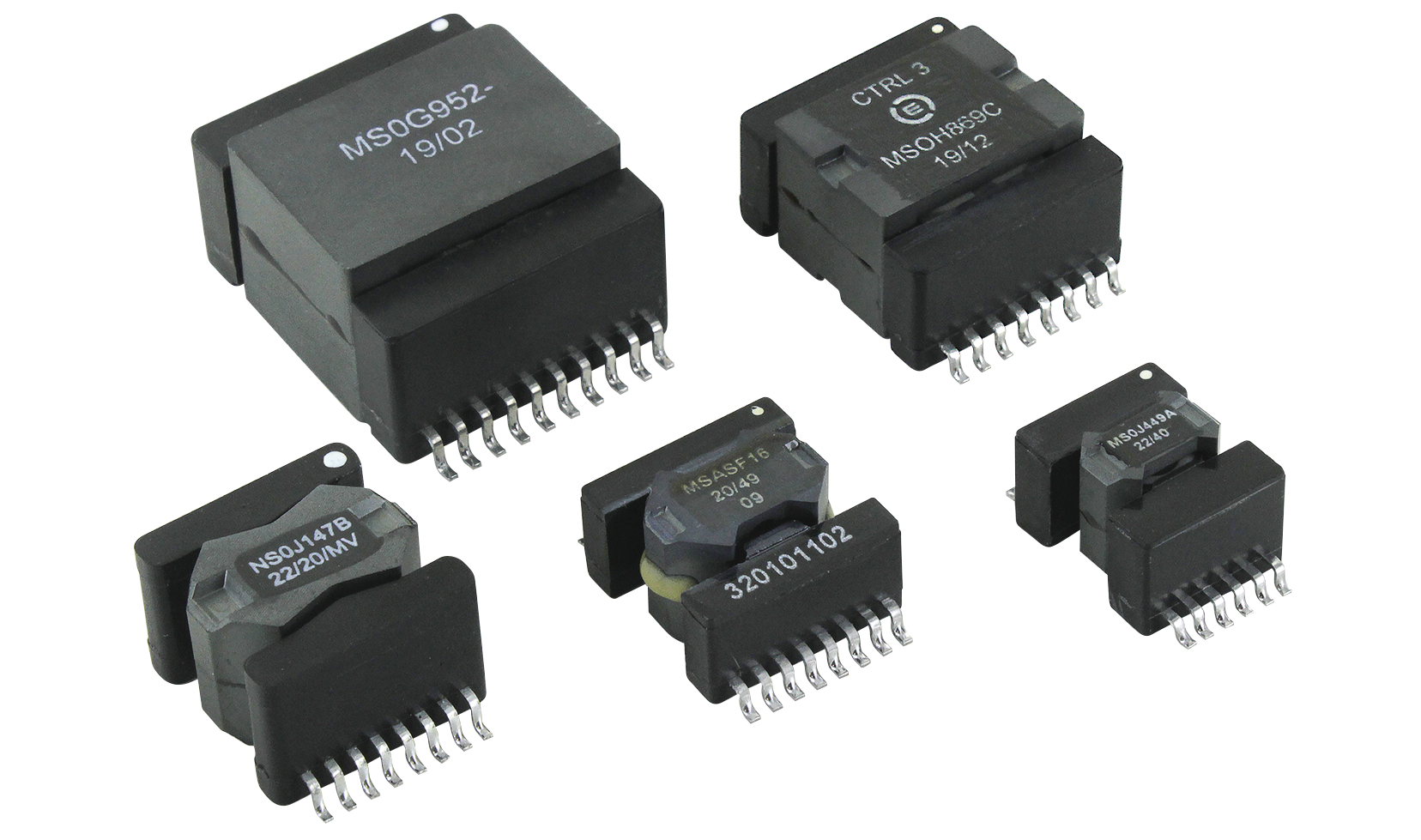

Power Inductors

Filtre

Operating Temp

-55°C

125°C

Mounting

SMD

Frequency

1MHz

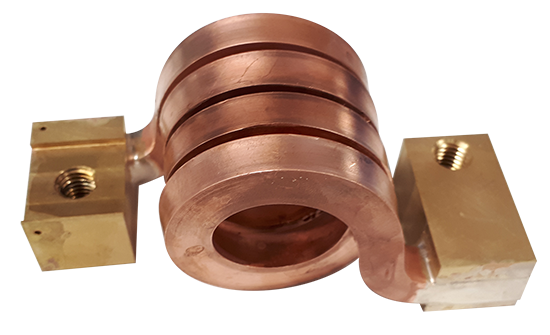

Winding flat wire on flange / Helical winding

Custom example

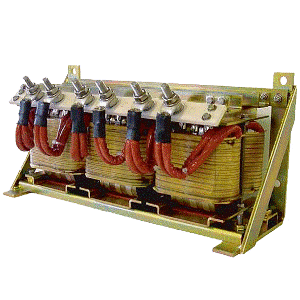

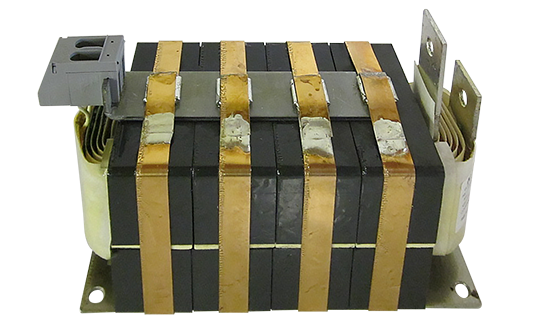

C Cores Assemblies (Inductors)

High temperature

Operating Temp

240°C

Height

300mm

Frequency

50Hz

500Hz

|

Name

|

Download

|

Operating Temp

|

Height

|

Mounting

|

Frequency

|

Power

|

Current

|

Inductance

|

Peak Current

|

Accuracy

|

RoHS

|

Ratio

|

Diameter (Outside Diameter)

|

Length

|

Weight

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CCM Series (Chameleon Concept Magnetics) | -55°C ~ 125°C | - | SMD | 1MHz | - | 17.7A | 1µH ~ 4679µH | 22.1A | - | - | - | - | - | - | |

| SESI Series | -55°C ~ 125°C | - | SMD | 1MHz | - | 0.045A ~ 24A | 1µH ~ 6800µH | 27.6A | - | - | - | - | - | - | |

| Power supply inductor | -40°C ~ 180°C | - | - | 50Hz | - | 60A | 600µH | 70A | - | - | - | - | - | - | |

| Custom inductor | -40°C ~ 180°C | - | - | 50Hz | - | 242A | 150µH | 280A | - | - | - | - | - | - | |

| Filtering Choke | -40°C ~ 180°C | - | - | 60Hz | - | 150A | 1.1mH | 175A | - | - | - | - | - | - | |

| Harmonic Choke 50Hz | -40°C ~ 180°C | - | - | 60Hz | - | 117A | - | - | - | - | - | - | - | - | |

| Battery inductor 50Hz | -40°C ~ 180°C | - | - | 50Hz | - | 600A | - | - | - | - | - | - | - | - | |

| ESI 01 | -55°C ~ 125°C | - | - | 1MHz | - | 0.26A ~ 2.1A | 2.69µH ~ 151.2µH | - | - | - | - | - | - | - | |

| ESI 07 | -55°C ~ 125°C | - | - | 1MHz | - | 0.6A ~ 2.9A | 0.42µH ~ 8.42µH | 6A | - | - | - | - | - | - | |

| Winding flat wire on flange / Helical winding | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| Shaped Ferrite assembly | 0°C ~ 240°C | - | - | 1MHz | - | 60A ~ 270A | 5µH ~ 20000µH | - | - | - | - | - | - | - | |

| Overmolded Cores Assembly (Inductors) | - | 320mm | - | 12kHz | - | 0A ~ 316A | 30µH | - | - | - | - | - | - | - | |

| C Cores Assemblies (Inductors) | 240°C | 300mm | - | 50Hz ~ 500Hz | - | 2A ~ 240A | 600µH ~ 3mH | - | - | - | - | - | - | - |

Power supply inductor

Custom example

New

Custom inductor

Custom example

Filtering Choke

Custom example

Harmonic Choke 50Hz

Custom example

Battery inductor 50Hz

Custom example

Winding flat wire on flange / Helical winding

Custom example

Shaped Ferrite assembly

Custom example

Overmolded Cores Assembly (Inductors)

Custom example

C Cores Assemblies (Inductors)

High temperature

Power Inductors

Our high-quality power inductors components ensure optimal performance and reliability in your applications. From compact designs for space-constrained environments to high-current handling capabilities for robust power systems, our power inductors cater to diverse needs.

Whether you're designing power converters, DC-DC converters, or voltage regulators, Exxelia's power inductors deliver exceptional performance to drive innovation forward.

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service

Contact