EMC - TEMPEST - HEMP

|

Name

|

Download

|

Voltage Rated DC

|

Capacitance

|

Diameter (Outside Diameter)

|

Operating Temp

|

Mounting

|

Current

|

Insertion Loss

|

Sealing

|

Cell Type

|

|---|---|---|---|---|---|---|---|---|---|---|

| PIF MIL | 28V ~ 240V | - | - | -40°C ~ 55°C | - | 10A | 80dB | - | - | |

| TY series | 100V ~ 200V | - | - | -40°C ~ 55°C | Feedthru | 1A | 100dB | - | - | |

| TIF series | 100V ~ 200V | - | - | -40°C ~ 55°C | Feedthru | 1A | 100dB | - | - | |

| OPT series | 100V ~ 200V | - | - | -40°C ~ 55°C | Feedthru | 1A | 100dB | - | - | |

| MAX-MFX | 100V ~ 200V | - | - | -40°C ~ 55°C | Feedthru & Zoning | 1A | 100dB | - | - | |

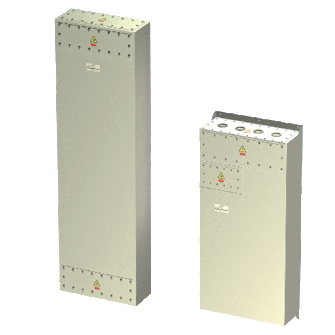

| BC-88 series | 220V ~ 400V | - | - | -40°C ~ 55°C | Feedthru & Zoning | 1250A | 80dB | - | - | |

| BC-91 | 220V ~ 400V | - | - | -40°C ~ 55°C | Feedthru | 1250A | 100dB | - | - | |

| BCM series | 220V ~ 400V | - | - | -40°C ~ 55°C | Feedthru | 800A | 100dB | - | - | |

| BCC | 28V ~ 400V | - | - | -40°C ~ 55°C | Feedthru & Zoning | 800A | 100dB | - | - | |

| BCU | - |

220V ~ 400V | - | - | -40°C ~ 55°C | Feedthru | 800A | 100dB | - | - |

| BDP series | 220V ~ 400V | - | - | -40°C ~ 55°C | Feedthru | 1250A | 80dB | - | - | |

| HDP series | 220V ~ 400V | - | - | -40°C ~ 55°C | Feedthru | 1250A | 100dB | - | - | |

| HDPC series | 28V ~ 90V | - | - | -40°C ~ 55°C | Feedthru | 1250A | 100dB | - | - |

EMC - TEMPEST - HEMP

At Exxelia, we specialize in providing cutting-edge solutions for Electromagnetic Compatibility (EMC), TEMPEST, and HEMP protection, ensuring the integrity and reliability of your critical electronic systems in even the most demanding environments.

Our EMC solutions are designed to mitigate electromagnetic interference (EMI) and ensure compliance with stringent regulatory standards. From innovative filtering technologies to custom shielding solutions, we offer a comprehensive range of products and services tailored to your specific requirements.

In the realm of TEMPEST protection, Exxelia excels in safeguarding sensitive information from electromagnetic emanations. Our TEMPEST-certified products are engineered to prevent unauthorized access to classified data by mitigating the risks posed by compromising emanations.