MIL QPL

|

Name

|

Download

|

Dielectric

|

Capacitance

|

Operating Temp

|

Voltage Rated DC

|

Terminations or connections

|

|---|---|---|---|---|---|---|

| MIL-PRF-39022/1 | - | 47pF ~ 12pF | 55°C ~ 125°C | 50V ~ 600V | - | |

| MIL-PRF-39022/2 | - | 47pF ~ 8.2pF | -55°C ~ 125°C | 200V ~ 400V | - | |

| MIL-PRF-39022/8 | - | 0.01pF ~ 12pF | -55°C ~ 125°C | 50V ~ 600V | - | |

| MIL-PRF-39022/12 | - | 0.01pF ~ 10pF | -55°C ~ 85°C | 50V ~ 600V | - | |

| MIL-PRF-39022/13 | - | 0.01pF ~ 22pF | -55°C ~ 125°C | 50V ~ 600V | - | |

| MIL-PRF-83421/2 | - | 0.001pF ~ 25pF | -55°C ~ 105°C | 100V ~ 400V | - | |

| MIL-PRF-83421/6 | - | 0.001pF ~ 22pF | -55°C ~ 125°C | 30V ~ 400V | - | |

| MIL-PRF-19978/1 | Paper / Polyester | 0.001pF ~ 39pF | -65°C ~ 125°C | 30V ~ 1000V | Axial | |

| MIL-PRF-19978/10 | Paper / Polyester | 0.001pF ~ 1pF | -65°C ~ 125°C | 200V ~ 1000V | Axial | |

| MIL-PRF-19978/11 | Paper / Polyester | 0.001pF ~ 1pF | -65°C ~ 125°C | 200V ~ 1000V | Axial | |

| MIL-C-19978/12 | Paper / Polyester | 0.0039pF ~ 1pF | -65°C ~ 125°C | 200V ~ 600V | Axial | |

| MIL-PRF-19978/13 | Polyester / Foil | 0.001pF ~ 10pF | -65°C ~ 85°C | 30V ~ 1000V | Axial | |

| MIL-PRF-19978/14 | Polyester / Foil | 0.001pF ~ 10pF | -65°C ~ 85°C | 30V ~ 1000V | Axial |

MIL QPL

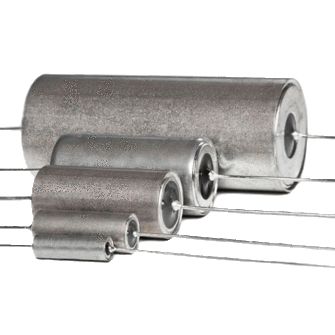

Exxelia offers a comprehensive range of MIL QPL-certified film and mica capacitors, designed to meet the highest reliability standards required by aerospace, defense, and high-performance industrial applications.

Our MIL-qualified capacitors comply with rigorous military specifications, ensuring exceptional durability, stability, and performance under extreme environmental conditions. With approvals such as MIL-PRF-83446 for mica capacitors, as well as MIL-PRF-55514 and MIL-PRF-19978 for film capacitors, Exxelia provides components that guarantee superior electrical characteristics and long operational lifetimes.

Whether for power electronics, filtering, or energy storage, our MIL QPL-certified capacitors are trusted by major OEMs and defense organizations worldwide. Our expertise in high-reliability capacitors allows us to offer custom solutions tailored to the most demanding specifications.

Explore Exxelia’s MIL QPL capacitor portfolio to find the ideal solution for your critical applications.