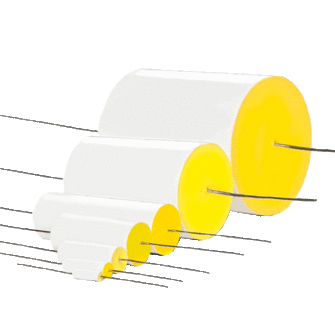

High Rel / High Precision

Filtre

Capacitance

1nF

1µF

Tolerance

±5%

±10%

+ 1 more

Operating Temp

-65°C

125°C

Capacitance

100nF

0.5µF

Tolerance

±5%

±10%

+ 1 more

Operating Temp

-40°C

85°C

Capacitance

1nF

10µF

Voltage Rated AC

32V

620V

Tolerance

±5%

±10%

+ 1 more

Capacitance

10nF

1µF

Voltage Rated AC

155V

500V

Tolerance

±10%

±20%

+ 1 more

Capacitance

1nF

1µF

Tolerance

±10%

±20%

+ 1 more

Operating Temp

-55°C

105°C

73X (730P & 731P)

Stability

Capacitance

22nF

10µF

Voltage Rated AC

100V

277V

Tolerance

±10%

±20%

+ 1 more

Capacitance

1nF

10µF

Voltage Rated AC

80V

400V

Tolerance

±5%

±10%

+ 1 more

Capacitance

10nF

10µF

Voltage Rated AC

125V

250V

Tolerance

±2%

±5%

+ 1 more

|

Name

|

Download

|

Capacitance

|

Voltage Rated AC

|

Tolerance

|

Operating Temp

|

RoHS

|

Voltage Rated DC

|

Dielectric

|

|---|---|---|---|---|---|---|---|---|

| 13X (131P & 132P) | 1nF ~ 1µF | - | ±5%, ±10%, ±20% | -65°C ~ 125°C | Non ROHS | 200V ~ 1000V | Polyester (PET) | |

| 409P | 100nF ~ 0.5µF | - | ±5%, ±10%, ±20% | -40°C ~ 85°C | - | 50V ~ 1000V | Polyester (PET) | |

| 442/410 | 1nF ~ 10µF | 32V ~ 620V | ±5%, ±10%, ±20% | -55°C ~ 125°C | Non ROHS | 50V ~ 600V | Polyester (PET) | |

| 700P | 10nF ~ 1µF | 155V ~ 500V | ±10%, ±20%, -10% | -55°C ~ 105°C | Non ROHS | 200V ~ 800V | Polypropelene (PP) | |

| 710P | 1nF ~ 1µF | - | ±10%, ±20%, -10% | -55°C ~ 105°C | Non ROHS | 200V ~ 800V | Polypropelene (PP) | |

| 73X (730P & 731P) | 22nF ~ 10µF | 100V ~ 277V | ±10%, ±20%, -10% | -55°C ~ 105°C | Non ROHS | 160V ~ 630V | Polypropelene (PP) | |

| 744G | 470nF ~ 3.5µF | - | ±10%, ±20%, -10% | -55°C ~ 105°C | Non ROHS | 600V ~ 600V | Polypropelene (PP) | |

| 810P & 859P | 1nF ~ 10µF | 80V ~ 400V | ±5%, ±10%, ±20% | -55°C ~ 125°C | Non ROHS | 50V ~ 400V | Polyphenylene sulf. (PPS) | |

| 832P | 1nF ~ 10µF | 40V ~ 200V | ±2%, ±5%, ±10% | -55°C ~ 125°C | Non ROHS | 63V ~ 400V | Polyphenylene sulf. (PPS) | |

| 859/860 | 10nF ~ 10µF | 125V ~ 250V | ±2%, ±5%, ±10% | -55°C ~ 125°C | Non ROHS | 125V ~ 250V | Polyphenylene sulf. (PPS) | |

| CA | 0.005nF ~ 0.1µF | - | ±1%, ±2%, ±5%, ±10% | -55°C ~ 125°C | ROHS | 63V ~ 1000V | Silvered Mica | |

| CMR Series | 5.1nF ~ 0.012µF | - | ±2% | -55°C ~ 125°C | ROHS | 50V ~ 500V | Silvered Mica | |

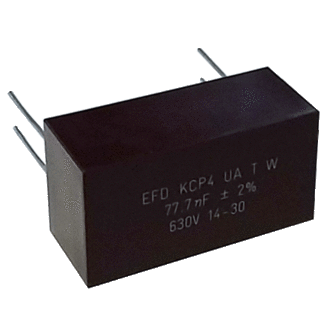

| KCP4 UA T | 7.5nF ~ 0.078nF | - | ±2%, ±5% | -55°C ~ 125°C | ROHS | 630V ~ 1000V | Polyphenylene sulf. (PPS) |

73X (730P & 731P)

Stability

744G

Low ESR

832P

High temperature

CA

Precision

CMR Series

Precision

KCP4 UA T

Stability

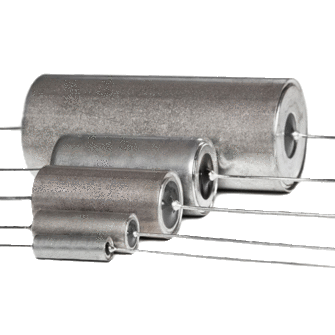

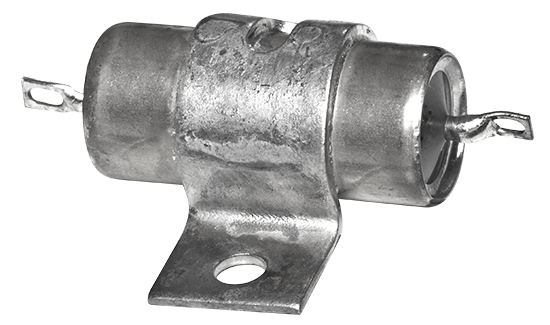

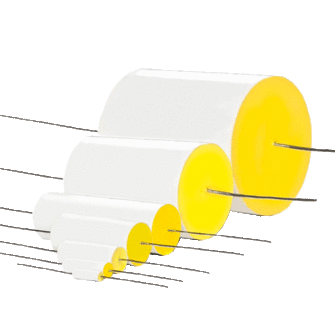

High Rel / High Precision

Explore Exxelia's High Reliability, High Precision Film Capacitors: Discover industry-leading performance and unmatched reliability in our selection of film capacitors. Engineered to meet the most demanding requirements, our capacitors ensure precision and durability in critical applications. Elevate your projects with Exxelia's trusted solutions for high-performance electronics.

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service

Contact