Slip Rings & Rotary Joints

Design your product

For more than 5O years Exxelia has been developing custom premium slip rings designed for high reliability applications such as radars, electro-optic payloads and drilling tools.

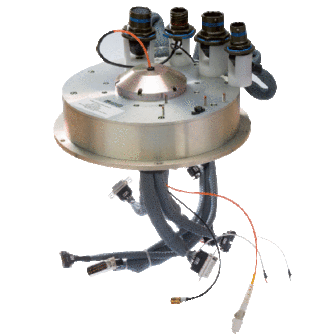

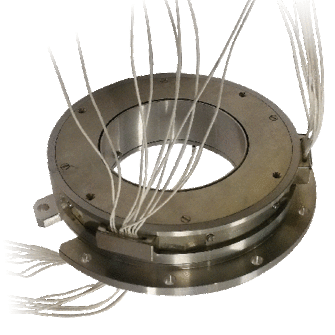

Exxelia extensive know-how allows to offer pancake, hollow shaft or high-speed slip rings as well as separate elements.

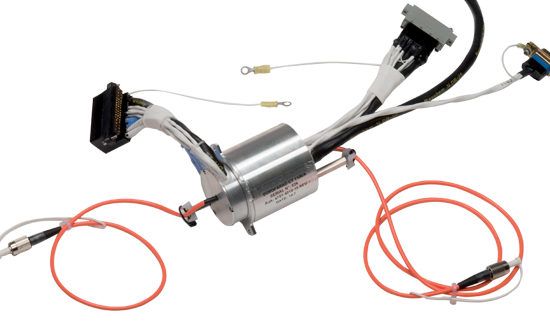

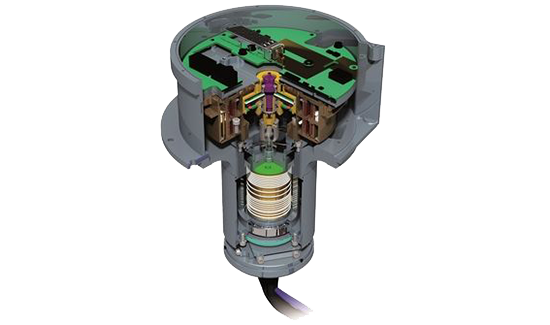

The group can also provide integrated Rotary Joint Assemblies (RJA) incorporating different elements such as Fiber Optic Rotary Joints (FORJ), Radio Frequency Rotary Joints (RFRJ), potentiometers or optical encoders etc...

50+ years

of experience

designing and producing slip rings

300+

different designs

built specifically to meet our client’s needs

100+

prestigious programs

for Aerospace, Defense, Oil&Gas and many more applications

Highlighted products

Frequently Asked Questions

Exxelia’s slip rings are designed with modular concepts and technological bricks, allowing for easy integration and scalability in complex systems, facilitating upgrades and maintenance.

Exxelia has been producing slip rings for more than 50 years. From this experience, it became apparent that when it comes to slip rings designed for high performance ruggedised systems, one size does not fit all. That's why all slip rings developed by Exxelia are built to specifications.

Hybrid slip rings by Exxelia integrate multiple functionalities such as electrical, optical, and fluidic transmission in a single unit, optimizing performance, space and weight in complex systems.

Military-grade slip rings from Exxelia are engineered for enhanced ruggedness, offering high shock, vibration and corosion resistance and compatibility with advanced communication systems and electro-optical payloads.

Yes, Exxelia provides customized slip rings with high IP ratings and corrosion-resistant materials, ideal for harsh marine and subsea environments that have proven their reliability on already existing prestigious programs.

Exxelia slip rings are designed for high reliability and performance, featuring integration with fiber optic rotary joints, encoders, RF joints and the capability to handle high power and high RPM, crucial for aerospace systems.

Exxelia adheres to rigorous testing protocols including performance, durability, and environmental testing to ensure high quality and reliability of its slip rings and sensors, specific control and qualifications process can be offered based on the slip ring operational requirements.

Exxelia slip rings use advanced materials and design methods to effectively dissipate heat, ensuring reliable operation under high thermal conditions.

Exxelia is certified EN 9100, a quality standard specific to the aerospace, space, and defense sectors. Our facilities are also ISO 9001 certified (quality management), and some are certified ISO 13485 for medical devices. Other industry-specific standards, such as NADCAP or AQAP, may also apply depending on the products and markets.

The EN 9100 standard ensures a rigorous quality management system tailored to the critical requirements of the aerospace, space, and defense industries. It is required by major OEMs such as Airbus, Safran, Thales, or CNES. This certification guarantees product traceability, risk management, and compliance with international standards.

Yes, some of our facilities are ISO 13485 certified, the quality standard for medical devices. This certification enables Exxelia to design and manufacture components (such as coils, sensors, or capacitors) used in high-reliability medical equipment, including MRI scanners, ventilators, and imaging systems.

The railway industry demands durability, reliability, and long service life. While a dedicated certification like EN 9100 is not required, Exxelia applies IRIS standards and complies with IEC/EN regulations specific to railway applications. Our quality processes ensure component compliance for trains, metros, and tramways, including fire safety and electromagnetic compatibility.

Yes. Exxelia meets defense industry requirements through its EN 9100 certification and compliance with military standards (MIL-STD, STANAG). Our components are qualified for critical applications such as RF systems, embedded electronics, guided munitions, or radar systems. Some products are also subject to customer-specific qualification procedures.

Still have questions ?