Optical Rotary Encoders

Filtre

Operating Temp

-45°C

115°C

Diameter (Outside Diameter)

27mm

Mounting

Servo

Flange

Operating Temp

-45°C

115°C

Diameter (Outside Diameter)

32mm

Mounting

Servo

Flange

Operating Temp

-55°C

115°C

Diameter (Outside Diameter)

34mm

Mounting

Servo

Flange

Operating Temp

-55°C

115°C

Diameter (Outside Diameter)

51mm

Mounting

Servo

Flange

Operating Temp

-55°C

115°C

Diameter (Outside Diameter)

55mm

Mounting

Servo

Flange

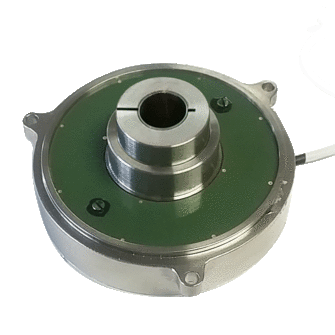

Custom Optical Encoders

Custom example

Operating Temp

-55°C

115°C

Diameter (Outside Diameter)

22mm

55mm

Mounting

Servo

Flange

|

Name

|

Download

|

Operating Temp

|

Diameter (Outside Diameter)

|

Mounting

|

Sealing

|

Housing Diameter

|

Length

|

Weight

|

Vibrations

|

Resolution

|

Accuracy

|

Shocks

|

Rotation speed

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AE09 | -45°C ~ 115°C | 22mm | Servo, Flange | IP40 | 20mm ~ 30mm | 18mm | 35g | 20g.acc | up to 19 bits | Arcmin | 50g.acc | 300rpm | |

| AE11 | -45°C ~ 115°C | 27mm | Servo, Flange | IP40 | 20mm ~ 30mm | 24mm | 40g | 20g.acc | up to 19 bits | Arcmin | 50g.acc | 300rpm | |

| AE13 | -45°C ~ 115°C | 32mm | Servo, Flange | IP40 | 30mm ~ 45mm | 11.5mm | 40g | 20g.acc | up to 21 bits | +/- 40 arc sec | 50g.acc | 300rpm | |

| AE15 | -55°C ~ 115°C | 34mm | Servo, Flange | IP40 | 30mm ~ 45mm | 10mm | 60g | 20g.acc | up to 21 bits | +/- 40 arc sec | 50g.acc | 300rpm | |

| AE23 | -55°C ~ 115°C | 51mm | Servo, Flange | IP40 | 45mm | 12.4mm | 200g | 20g.acc | up to 21 bits | +/- 20 arc sec | 50g.acc | 300rpm | |

| AE23H | -55°C ~ 115°C | 55mm | Servo, Flange | IP40 | 45mm | 18mm | 100g | 20g.acc | up to 21 bits | +/- 20 arc sec | 50g.acc | 300rpm | |

| Custom Optical Encoders | - |

-55°C ~ 115°C | 22mm ~ 55mm | Servo, Flange | Rotary or Linear, IP40 | 20mm ~ 45mm | 10mm ~ 24mm | 35mg ~ 200mg | 20g.acc | up to 21 bits | - | - | - |

Optical Rotary Encoders

Optical sensing provides the highest resolution, accuracy, operating speed, and reliability, as well as long life operation in most environments (shocks, vibrations, large operating temperature range,...).

Each product can be customized and fully custom versions are available.

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service

Contact