Microwave Tuning Elements

|

Name

|

Download

|

Frequency

|

Q Factor

|

Rod material

|

Magnetization

|

Notes

|

Wavelength

|

Frequency band

|

Brushing thread

|

Section surface

|

Q x f Factor

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| Custom Invar Tuning Element | - | - | Invar | - | ESA_3010 compliant | - | Ku to Q | Custom | - | - | |

| AT 6924-X SL ROHS | - | - | Brass | - | ESA_3010 compliant | - | X and K | .120-80 | - | - | |

| AT 6925-x SL ROHS | - | - | Brass | - | ESA_3010 compliant | - | C and X | .190-64 | - | - | |

| AT 6926-x SL ROHS | - | - | Brass | - | ESA_3010 compliant | - | C and X | .234-64 | - | - | |

| AT 6927-0 SL ROHS | - | - | Brass | - | ESA_3010 compliant | - | C and X | .234-64 | - | - | |

| AT 6928-X SL ROHS | - | - | Brass | - | ESA_3010 compliant | - | C | .234-64 | - | - | |

| AT 6929-0 SL ROHS | - | - | Brass | - | ESA_3010 compliant | - | C | .190-64 | - | - | |

| AT 6948-0 SL ROHS | - | - | Brass | - | ESA_3010 compliant | - | C and X | .312-64 | - | - | |

| AT 6965-0 SL ROHS | - | - | Brass | - | ESA_3010 compliant | - | L and S | .469-64 | - | - | |

| AT 6501-x ROHS | - | - | Brass | - | ESA_3010 compliant | - | X to K | No bushing | - | - | |

| AT 6995-x ROHS | - | - | Brass | - | ESA_3010 compliant | - | X to K | No bushing | - | - | |

| AT 6996-x ROHS | - | - | Brass | - | ESA_3010 compliant | - | C and X | No bushing | - | - | |

| AT 6997-x ROHS | - | - | Brass | - | ESA_3010 compliant | - | C and X | No bushing | - | - |

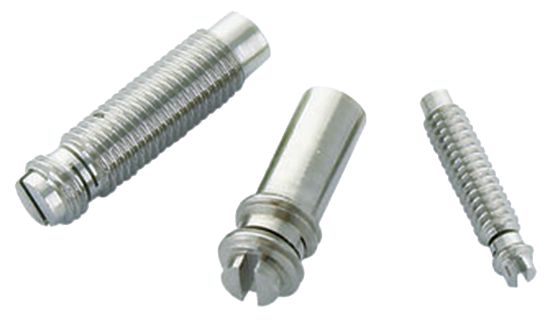

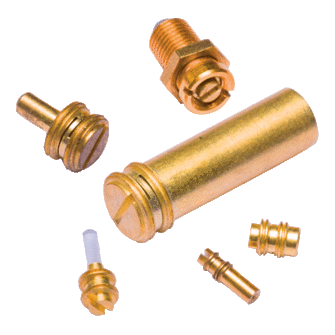

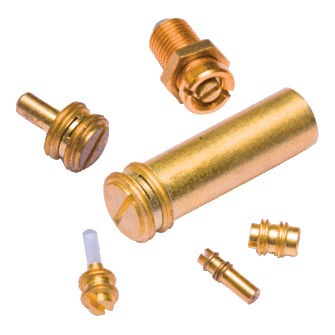

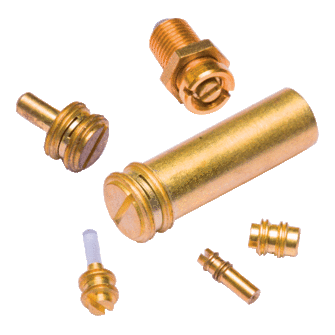

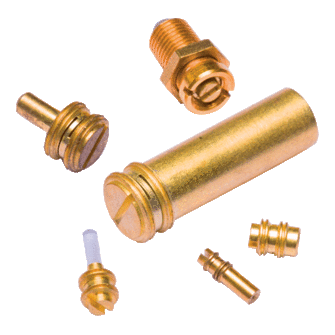

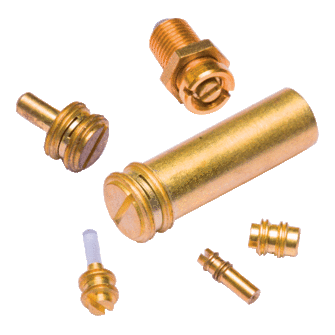

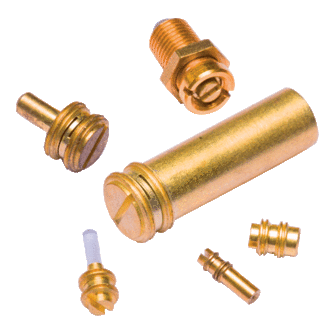

Microwave Tuning Elements

Our Microwave Tuning Elements serve as indispensable components in various high-frequency applications, including combined and interdigital filters, coaxial structures, and waveguide circuitry. Exxelia's tuning elements ensure excellent precision and low loss, guaranteeing reliable and high performance even in demanding environments. The optional self-locking capability eliminates the hassle of locking nuts, simplifying the tuning process for operators and ensures exceptional tuning stability and low dynamic noise.

Our tuning elements are available in various materials for extended applications up to Ka band and beyond: metallic, dielectric (Sapphire, Quartz, Alumina), and resistive variants. Furthermore, customization options such as Gold or Silver plating, as well as chromate finishing, enable tailored solutions to match specific application requirements with precision.

One of our standout features lies in the utilization of advanced materials such as Invar alloy. Recognizing the importance of temperature stability in microwave filters, especially for narrow bandwidth high-frequency filters, we leverage Invar alloy's superior Coefficient of Thermal Expansion (CTE) to achieve optimal temperature characteristics.

Our dedicated team of experts stands ready to collaborate with our customers, offering custom design solutions tailored to their unique requirements. Whether it is a standard products or specialized designs, our Microwave Tuning Elements are engineered to maximize efficiency, precision, and reliability of microwave circuits. ROHS compliant and high-reliability versions are available upon request.