Exxelia SVM is a company within the Exxelia Group with over 35 years of experience in the design, development, and manufacturing of coils and transformers, for both high-frequency and low-frequency applications. This extensive expertise allows Exxelia SVM to offer reliable technical solutions tailored to a wide range of demanding and often critical requirements.

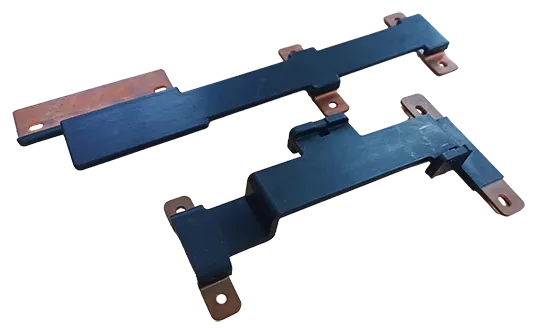

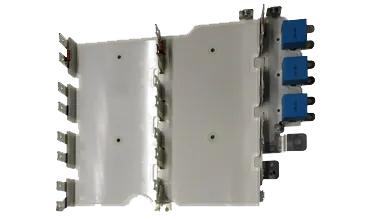

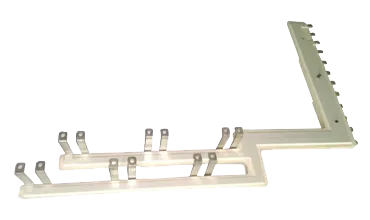

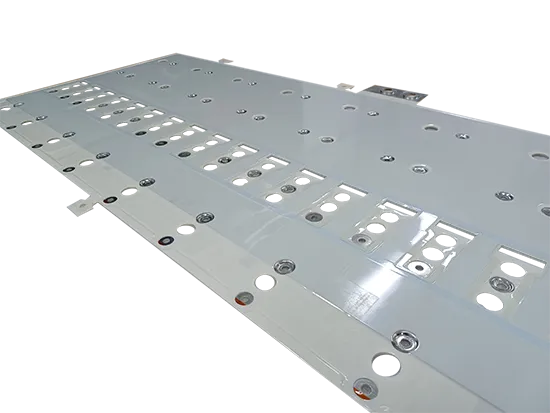

For more than 12 years, Exxelia SVM has also specialized in the design and production of busbars with a variety of technologies and finishes, including:

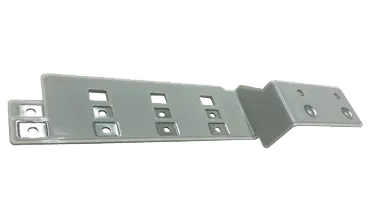

epoxy powder coating,

PVC coating,

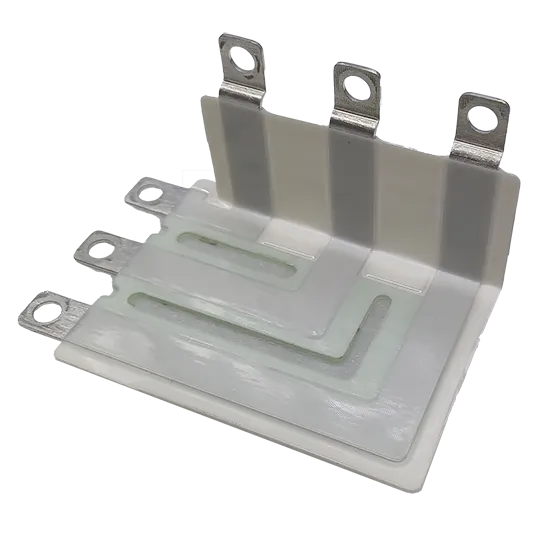

laminated busbars,

flexible busbars,

resin-cast busbars,

and surface finishes such as nickel plating, gold plating, silver plating, brazing, and tin plating.

These busbars are used in demanding environments, particularly in the healthcare and automotive industries, where high quality, reliability, and performance are essential.

Exxelia SVM’s mission is to address the complex and critical needs of design and manufacturing engineers in the electronics and electrical industries. The company supports its customers from design to mass production, offering full technical support to turn design concepts into manufacturable products.

With its long-standing experience in the design of transformers, inductors, and various electromagnetic components, Exxelia SVM continuously improves product quality. This know-how also enables productivity gains without compromising quality, ensuring consistent performance and competitive pricing for its customers.

Exxelia SVM is also characterized by strong vertical integration, which provides a high degree of flexibility and self-sufficiency in its manufacturing processes. This integration includes:

the design of bobbins,

the design and fabrication of injection molds,

the manufacture of bobbins using both thermoset (phenolic) and thermoplastic materials, from standard to high-performance grades,

an in-house tool room for precision machining of plastics and metals to meet exacting specifications, especially for rigid mounting systems,

the design and production of customized packaging materials to meet specific transportation needs, whether by road, air, or sea.

With a monthly production capacity exceeding 10 million parts, Exxelia SVM is one of the largest manufacturers of coils and transformers in India, serving low-, mid-, and high-volume production demands.

Exxelia SVM’s components are used across a variety of sectors, including:

Exxelia SVM serves international customers in the United States, Israel, France, China, and India, demonstrating its ability to meet global technical, regulatory, and logistical standards across a wide range of industries.