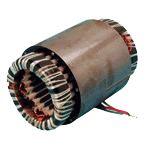

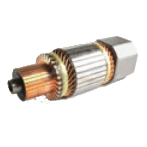

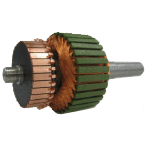

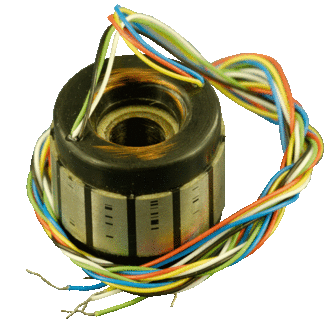

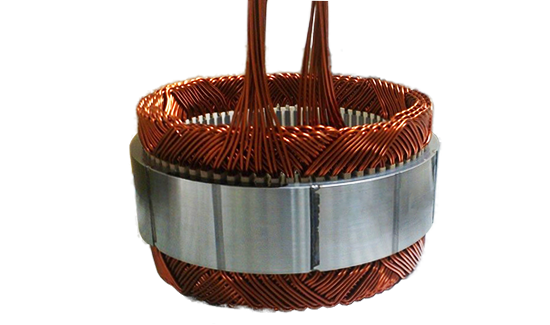

Rotors & Stators winding

Filtre

Motor & Stator

Custom example

Operating Temp

-60°C

120°C

Diameter (Outside Diameter)

100mm

Length

120mm

|

Name

|

Download

|

Operating Temp

|

Height

|

Mounting

|

Frequency

|

Power

|

Current

|

Inductance

|

Peak Current

|

Accuracy

|

RoHS

|

Ratio

|

Diameter (Outside Diameter)

|

Length

|

Weight

|

Notes

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stator 250 | - | - | - | - | - | - | - | - | - | - | - | 250mm | 350mm | 20Kg | - | |

| Rotor 30 | - | - | - | - | - | - | - | - | - | - | - | 30mm | 70mm | 200g | - | |

| Stator 40 | - | - | - | - | - | - | - | - | - | - | - | 40mm | 75mm | 400g | - | |

| Rotor 20 | - | - | - | - | - | - | - | - | - | - | - | 20mm | 55mm | 150g | - | |

| Stator 70 | - | - | - | - | - | - | - | - | - | - | - | 70mm | 80mm | 1.8Kg | - | |

| Rotor 25 | - | - | - | - | - | - | - | - | - | - | - | 25mm | 40mm | 180g | - | |

| Stator 75 | - | - | - | - | - | - | - | - | - | - | - | 75mm | 50mm | 300g | - | |

| Rotor 40 | - | - | - | - | - | - | - | - | - | - | - | 40mm | 50mm | 200g | - | |

| Stator 100 | - | - | - | - | - | - | - | - | - | - | - | 100mm | 120mm | 3.8Kg | - | |

| Stator 20 | - | - | - | - | - | - | - | - | - | - | - | 20mm | 30mm | 80g | - | |

| Stator 180 | - | - | - | - | - | - | - | - | - | - | - | 180mm | 120mm | 8Kg | - | |

| Motor & Stator | -60°C ~ 120°C | - | - | - | - | - | - | - | - | - | - | 100mm | 120mm | 3.8Kg | for flight control |

Stator 250

Custom example

Rotor 30

Custom example

Stator 40

Custom example

Rotor 20

Custom example

Stator 70

Custom example

Rotor 25

Custom example

Stator 75

Custom example

Rotor 40

Custom example

Stator 100

Custom example

Stator 20

Custom example

Stator 180

Custom example

Motor & Stator

Custom example

Rotors & Stators winding

Exxelia offers design support and expertise to the development of rotors and stators for use up to 220°C. This demanding design capability together with strong engineering experience, in-depth winding, moulding expertise and manufacturing competencies, enable Exxelia to provide optimized solutions from the design phase to mass production.

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service

Contact