Position Sensors

Choose or Design your product

Exxelia has been developing contact and contactless position sensors for nearly 50 years for all high reliability applications including aviation, space and defense.

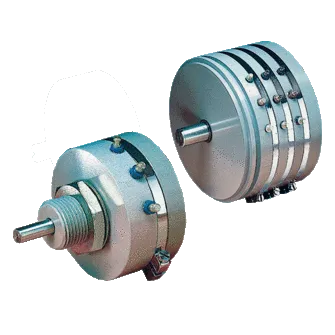

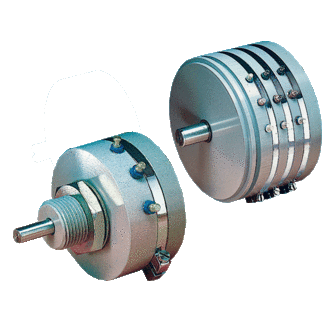

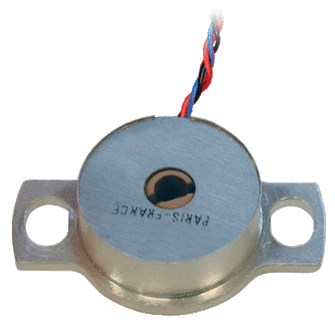

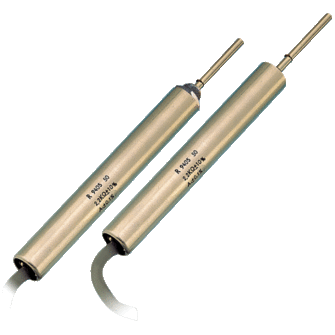

Exxelia offers optical encoders as well as linear & rotary potentiometers in all sizes, from miniature to the largest dimensions.

Products are available as catalog items and all can be slightly or deeply modified to respond to any mechanical, thermal and environmental requirements. Fully customized versions are also available.

Up to <20"

accuracy

Up to <0.01%

of linearity

Highlighted products

Frequently Asked Questions

Customized potentiometers can be specified using a detailed order code that includes segments for nominal resistance, linearity, electrical travel, mechanical options, and compliance. Contact technical support for assistance with specific configurations.

The starting torques range from ≤ 0.1 N.cm for miniature models to ≤ 5 x 10–3 N.m for models with precision bearings.

The potentiometer series includes single-turn rotary potentiometers, multi-turn rotary potentiometers, rectilinear potentiometers, and pancake potentiometers. These are designed to suit a wide range of applications from precise position sensing to control systems.

The core technologies include wirewound, conductive plastic, and hybrid elements, providing various performance characteristics such as high resolution, long life, and excellent linearity.

Potentiometers undergo rigorous testing, including:

- Micro-linearity and scale factor measurements

- Vibration and shock testing

- Environmental testing for thermal cycling, humidity, and salt fog resistance

These potentiometers are designed to withstand high levels of vibration and shock:

- Vibration resistance: up to 20 g, 1.5 mm, 10 to 500 Hz

- Shock resistance: up to 50 g, ½ sine, 11 ms

- General Technical Data

Exxelia is certified EN 9100, a quality standard specific to the aerospace, space, and defense sectors. Our facilities are also ISO 9001 certified (quality management), and some are certified ISO 13485 for medical devices. Other industry-specific standards, such as NADCAP or AQAP, may also apply depending on the products and markets.

The EN 9100 standard ensures a rigorous quality management system tailored to the critical requirements of the aerospace, space, and defense industries. It is required by major OEMs such as Airbus, Safran, Thales, or CNES. This certification guarantees product traceability, risk management, and compliance with international standards.

Yes, some of our facilities are ISO 13485 certified, the quality standard for medical devices. This certification enables Exxelia to design and manufacture components (such as coils, sensors, or capacitors) used in high-reliability medical equipment, including MRI scanners, ventilators, and imaging systems.

The railway industry demands durability, reliability, and long service life. While a dedicated certification like EN 9100 is not required, Exxelia applies IRIS standards and complies with IEC/EN regulations specific to railway applications. Our quality processes ensure component compliance for trains, metros, and tramways, including fire safety and electromagnetic compatibility.

Yes. Exxelia meets defense industry requirements through its EN 9100 certification and compliance with military standards (MIL-STD, STANAG). Our components are qualified for critical applications such as RF systems, embedded electronics, guided munitions, or radar systems. Some products are also subject to customer-specific qualification procedures.

Still have questions ?