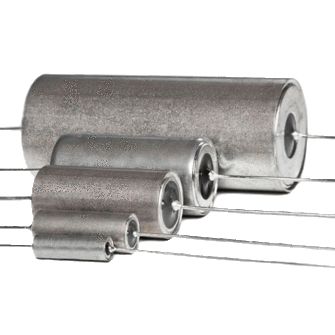

Typical Applications:

- Energy Storage

- Filtering

- Timing

Compliance and certifications

MIL

Would you like to ajust a little something?

Customize it

1document

Success Stories

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service.

Contact