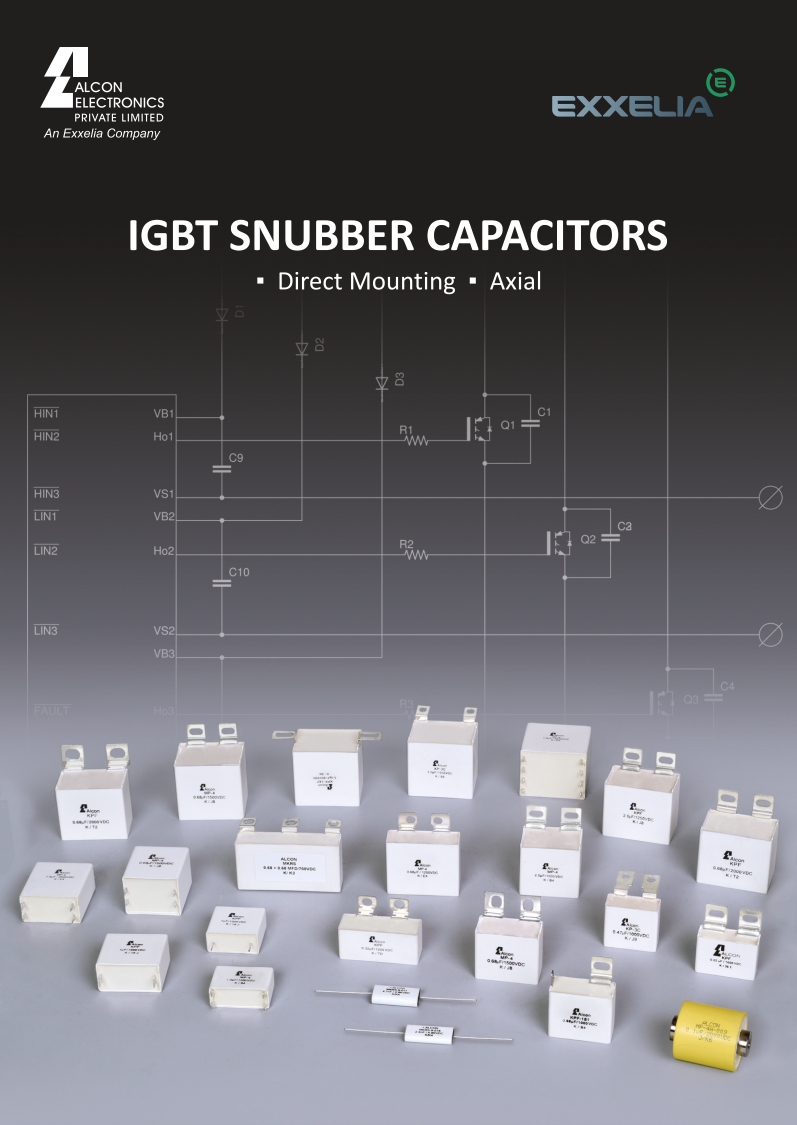

Typical applications :

- DC filtering ; Motor drives

- Inverters (wind, solar, electric vehicle)

- Induction heaters

- High Frequency and High Ripple Current Applications like High Frequency PWM Inverters, High KVA On-Line UPS, Telecom SMPS, Solar Inverters, Wind-Mill Power Suppliers.

Generic capacitance tolerance is ±10% but ±5% can be done on request.

|

PN

|

Capacitance

|

Tolerance

|

Operating Temp

|

RoHS

|

Voltage Rated DC

|

|---|---|---|---|---|---|

| SD000900700AP0Y20STDK01 | 90µF | ±10% | - | - | 700V |

| SD001450700AP0Y50STDK01 | 145µF | ±10% | - | - | 700V |

| SD002000700AP0Y60STDK01 | 200µF | ±10% | - | - | 700V |

| SD002650700AP0Y70STDK01 | 265µF | ±10% | - | - | 700V |

| SD000850900AP0Y20STDK01 | 85µF | ±10% | - | - | 900V |

| SD001200900AP0Y50STDK01 | 120µF | ±10% | - | - | 900V |

| SD001600900AP0Y60STDK01 | 160µF | ±10% | - | - | 900V |

| SD002000900AP0Y70STDK01 | 200µF | ±10% | - | - | 900V |

| SD000551000AP0Y20STDK01 | 55µF | ±10% | - | - | 1V |

| SD000701000AP0Y20STDK01 | 70µF | ±10% | - | - | 1V |

| SD001001000AP0Y50STDK01 | 100µF | ±10% | - | - | 1V |

| SD001301000AP0Y60STDK01 | 130µF | ±10% | - | - | 1V |

| SD001501000AP0Y70STDK01 | 150µF | ±10% | - | - | 1V |

Compliance and certifications

IEC

Would you like to ajust a little something?

Customize it

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service.

Contact