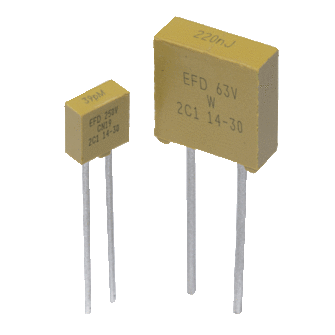

TCE, TCX, TCN, TXR Molded Series

Stability

High reliability

- High Rel capacitors

- Radial leaded

- High thermal and voltage stability

- Formerly under the reference: TCE11, TCE13, TCE202, TCE204, TCE263, TCE50, TCE52, TCE53, TCE54, TCE60, TCE61, TCE62, TCE63, TCE64, TCN15, TCN16, TCN19, TCN30, TCN31, TCN50, TCN60, TCN61, TCN62, TCN63, TCN64

-

Capacitance

1pF ~ 4.7µF

-

Voltage Rated DC

25V ~ 500V

-

Tolerance

±1%, ±2%, ±5%, ±10%, ±20%

-

Mounting

Radial

-

Operating Temp

-55°C ~ 125°C

-

RoHS

ROHS, Non ROHS

-

Case size

-

-

Dielectric

NPO, BX, 2C1, X7R

Typical applications :

- Decoupling

- Filtering

The below Part Numbers reflect our high runners only.

Please contact us if you can't find your specifications.

|

PN

|

Capacitance

|

Voltage Rated DC

|

Tolerance

|

Mounting

|

Operating Temp

|

RoHS

|

Case size

|

|---|---|---|---|---|---|---|---|

| TCE11L - - - - - 10pF +/-5% 63 V - - | 10pF | 63V | ±5% | Radial | - | Non ROHS | - |

| TCE11L - - - - - 22pF +/-5% 63 V - - | 22pF | 63V | ±5% | Radial | - | Non ROHS | - |

| TCE11N - - - - - 220pF +/-5% 63 V - - | 220pF | 63V | ±5% | Radial | - | Non ROHS | - |

| TCE11L - CG - - - 1nF +/-1% 63 V - - | 1000pF | 63V | ±1% | Radial | - | Non ROHS | - |

| TCE11L - CG - - - 1000pF +/-5% 63 V - - | 1000pF | 63V | ±5% | Radial | - | Non ROHS | - |

| TCE11L - CG - - - 1nF+/-10% 63 V - - | 1000pF | 63V | ±10% | Radial | - | Non ROHS | - |

| TCE11L - CG - - - 1500pF +/-5% 63 V - - | 1500pF | 63V | ±5% | Radial | - | Non ROHS | - |

| TCE11L - CG - - - 1650pF +/-1% 63 V - - | 1650pF | 63V | ±1% | Radial | - | Non ROHS | - |

| TCE11L - CG - - - 2200pF +/-5% 63 V - - | 2200pF | 63V | ±5% | Radial | - | Non ROHS | - |

| TCE11L - CG - - - 2.2nF +/-10% 63 V - - | 2200pF | 63V | ±10% | Radial | - | Non ROHS | - |

| TCE11L - CG - - - 2700pF +/-5% 63 V - - | 2700pF | 63V | ±5% | Radial | - | Non ROHS | - |

| TCE11L - UJ - - - 2700pF +/-5% 63 V - - | 2700pF | 63V | ±5% | Radial | - | Non ROHS | - |

| TCE11L - - W - - 3.32nF +/-1%63 V - - | 3320pF | 63V | ±1% | Radial | - | ROHS | - |

Compliance and certifications

CECC

Would you like to ajust a little something?

Customize it

1document

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service.

Contact