Magnetics

Filtre

Power

8.5kW

Frequency

20kHz

50kHz

Weight

2.5Kg

Power

6.3kW

Frequency

50Hz

60Hz

Weight

60Kg

Power

20kW

Frequency

25kHz

|

Name

|

Download

|

Power

|

Frequency

|

Accuracy

|

Inductance

|

Operating Temp

|

Mounting

|

Current

|

Peak Current

|

Height

|

Ratio

|

Diameter (Outside Diameter)

|

Length

|

Weight

|

RoHS

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

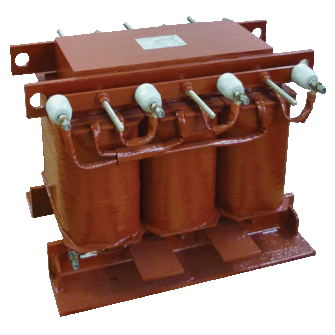

| 3-ph Transformer 150kVA | - |

150kW | 50Hz | - | - | - | Free (In-Line) | - | - | - | - | - | - | - | - |

| 3-ph Transformer 90kVA | - |

90kW | 50Hz ~ 5kHz | - | - | 200°C | Free (In-Line) | - | - | - | - | - | - | - | - |

| Single phase Transformer | - |

125kW | 4000Hz | - | - | - | Free (In-Line) | - | - | - | - | - | - | - | - |

| Integrated sub assemblies | 7kW ~ 2kW | 50Hz ~ 4000Hz | - | - | - | - | - | - | - | - | - | - | - | - | |

| Transformer 40KVA - Lamination assemblies | - |

40 | 60Hz | - | - | - | - | - | - | - | - | - | - | - | - |

| Transformer 60 kVA | - |

60kW | 50Hz | - | - | -40°C ~ 70°C | - | - | - | - | - | - | - | - | - |

| High Frequency Transformer | 8.5kW | 20kHz ~ 50kHz | - | - | - | - | - | - | - | - | - | - | 2.5Kg | - | |

| High Frequency Transformer 30kHz | 104kW | 30kHz | - | - | - | - | - | - | - | - | - | - | 33Kg | - | |

| Linear Isolation Transformer 7kW | 6.3kW | 50Hz ~ 60Hz | - | - | - | - | - | - | - | - | - | - | 60Kg | - | |

| High-Frequency transformer for High-Power naval solutions | 5kW | 100kHz | - | - | - | - | - | - | - | - | - | - | - | - | |

| 20kW/35µH Self + Transformer assembly for naval nuclear reactors | 20kW | 25kHz | - | - | - | - | - | - | - | - | - | - | - | - | |

| Low-Frequency isolated transformer for measuring chains | - | 60Hz | - | - | - | - | - | - | - | - | - | - | - | - | |

| Full Bridge 45kVA-10kHz | - |

45kW | 10kHz | - | - | 155°C | - | - | - | - | - | - | - | - | - |

3-ph Transformer 150kVA

Custom example

3-ph Transformer 90kVA

Custom example

New

Single phase Transformer

Custom example

Integrated sub assemblies

Custom example

Transformer 40KVA - Lamination assemblies

Custom example

Transformer 60 kVA

High power

New

New

High-Frequency transformer for High-Power naval solutions

Custom example

New

New

Low-Frequency isolated transformer for measuring chains

Custom example

Magnetics

Exxelia magnetics has more than 40 years experience in the design, industrialization and manufacturing of magnetics for Space, Civil aviation, Defense, Oli & Gas, Medical, Railway and industrial niche markets.

Exxelia actively works in partnership with the customer from prototype phase to production series.

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service

Contact